As well as a working master stone mason I am also Collegiate Assistant Clerk with the European Guild of Master Masons.

EGMM helped me when I was an apprentice and I was a member for 20 years before being asked to take over the Collegiate Assistant Clerks position in 2005, I was happy to accept and felt it my opportunity to give something back helping present and future craftsmen. Many are put off by the pomp and ceremony but I am proud to be involved with it, as it has formed over a many years and is the glue that holds together so many nationalities. When visiting a Hall in Italy or Turkey I feel instantly at home and in familiar surroundings even to the level of laughing with a fellow C. A. C about knocking over chairs when wearing your gown.

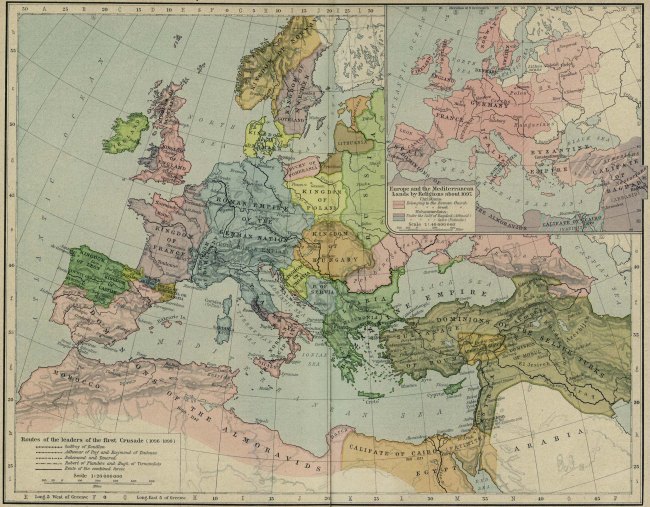

EGMM is a little known craftsman's guild formed around 1096 by Robert Duke of Normandy, among others, as part of the craft arm of the first Crusade to support the knights and their followers. At this time they became closely linked with the orders of monastic knights which explains many of our ceremonies and titles still used.

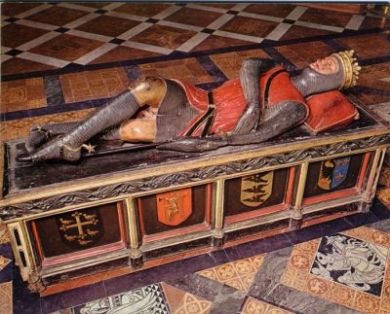

Robert of Normandy, Gloucester Cathedral

Originally formed across 12 city and national boundaries, there remain 12 companies within the Guild still known by their original names; Normandy, Holy Roman Empire, Byzantine Empire, Leon & Castile, Burgundy, Aragon, Catalonia, France, Zaragoza, Brittany, Venice & Navarre. Mainly states that one way or another were involved with the initial venture.

We have one Grand Master, 12 Masters, 12 Clerks, 12 Collegiate Assistant Clerks and Company Assistant Clerks, one for each company. In the UK or Normandy company we also have Wardens (upper and rented), and a Beadle in the manner of the Medieval Guilds.

Grand Master is a life long position, the Master of each company is elected quinquennially, the Clerk is the company's accountant, the Collegiate Assistant Clerk deals with education, training and helping members, and the Company Assistant Clerk deals with the running of the company and ceremonies.

Today it is a self financing, non profit making organisation truly diverse both racially and religiously, our company's ceremonial traditions cover the Jewish, Catholic, Orthodox Christian, Muslim and Protestant religions.

Throughout the turbulent history of Europe EGMM has kept it's head below the parapet, carrying on quietly with it's work, allowing the organisation to continue for over 1000 years virtually unknown and unmolested. Rather than giving a little help to the many, the ethos has always been to give total help and support to a few, as it was always the intention to nurture future craft masters, not jacks of all trades.

The Guild no longer has any connection with masonry projects as such, but through our members in over 20 modern countries we assist in training and education through our vast technical and historical archive and in the form of funding.

We still run several almshouses and supply financial help with bills etc. to elderly past members. This harks back to medieval times when we looked after the families of dead or injured members, helped with the education of their children and arbitrated between them and their employers or clients when needed. In the UK we were the forerunner to the operative stonemasons societies http://www.unionancestors.co.uk/Stonemasons.htm and a template for the early trade unions.

http://sjcritchley.com