Our clients have come to expect a high standard of marble carving from us and the only way we can achieve the highest quality and crispness is to get the marble at exactly the right length of time it has been out of the ground and work it before it dries and a calcareous layer is formed. This drying process is essential for exterior pieces especially in cold climates and for such pieces we allow them to dry before going out to the client.

When bought from UK suppliers or just ordering on the phone we can get marble that has possibly been quarried years ago, this is fine for flooring, cladding, table tops etc. but not for intricate carving, the longer the marble is out of the ground the more brittle it becomes as the natural moisture drawn up from the bed rock, what we call quarry sap, dries. When choosing limestone, sandstone and slate the need for really fresh material is virtually unimportant in most cases.

I make at least 4 visits a year to France Italy and Spain to purchase the marble for our more intricate pieces, going to the quarry to choose the marble in block form, then depending on block size either we cut the block down our self or if over 2 metres high we have the block cut down by the quarry.

When choosing I am looking for blocks with no flaws, a close grain and the correct hardness, colour and /or veining for the projects I have in mind.

Although obviously travelling around the continent is an enjoyable experience there is always the nagging fear that the blocks chosen are not suitable and this is only proven one way or other when the block is cut, possibly a month after being purchased. Thanks the bitter experience of making wrong choices in my younger days we are now as successful as can be expected when choosing a natural material formed under intense heat and pressure over huge stretches of time.

http://www.sjcritchley.com/front%20page.htm

Showing posts with label Carving. Show all posts

Showing posts with label Carving. Show all posts

Wednesday, 18 September 2013

Wednesday, 11 September 2013

Luxury items hand carved by a City of London master stonemason

My team of craftspeople and I hand carve marble, limestone, sandstone and slate fire surrounds, architectural dressed stone, garden & interior ornament and statuary in our two workshops in the UK, producing pieces for the heritage and design sectors through architcets, designers and direct to the public.

Although our work encompasses all architectural and design types including Gothic, Edwardian, Victorian, contemporary and modern, I am especially experienced in the period from the English Renaissance through English Baroque to Regency sometimes in design circles loosely named the English country house style.

In addition to training with a City of London company whose origins date back to 1690′s Aldgate, I have over 30 years experience working in and around The City of London, also working extensively in Georgian Bath and Cheltenham Spa. I gained experience and expertise whilst conserving and carving new architectural stone and interior pieces for some of the great palaces, stately homes, country house and churches in Britain, such as Queen’s House Greenwich, Woburn Abbey, Somerset House, St. Martin’s in the Fields, St. Paul’s Covent Garden, and Heythrop House.

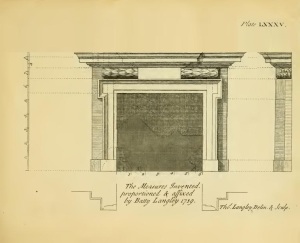

This gave me an insight and a greater understanding when interpreting and carving fire surrounds and ornamentation from designs by the likes of Inigo Jones, James Gibbs, William Chambers, Henry Flitcroft and from the contemporary pattern books by Batty Langley and William Halfpenny.

More recently, as well as the minimal contemporary ornament we have been making for interior designers for town houses and apartments, we have been producing many more classically inspired pieces used as a juxtaposition to the decoration in a modern setting . Fire surrounds, urns and pedestals, finials, columns, water features, panels, busts and statuary are all regularly produced.

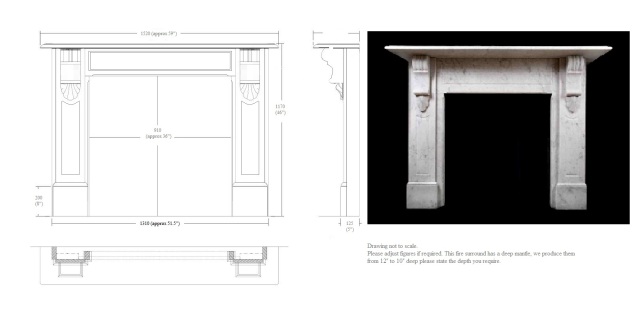

A large proportion of our design work involves carving fire surrounds to the design of an antique piece for architects and designers, the advantage of this for the client is, the antique although beautiful was made to suit a specific space, as such, much of the design and thinking that went in to the piece is now lost when placed in a new setting.

A new piece of the same quality and in many cases exactly the same material as the original can be produced allowing for the proportional changes to its surroundings and for ocular rectification to allow for light fall etc. These pieces are by no means just copies, they are new original pieces in the same way the piece we are working from are an original in the style of a classical design or which ever style it may be. There is no need make do when it comes to dimension or material.

Although all our fireplaces and ornamentation are still hand carved using techniques, tools and materials virtually unchanged since the 17th century, we do use technology to give a better service to the client. For example via web cam my clients can see their item on the bench in one of our UK workshops and talk to us in real time to discuss materials, design dimensions etc.

We supply items worldwide to dealers, architects, designers, developers, galleries and the public, with our main markets outside the UK being the USA and Asia.

Wednesday, 21 August 2013

Neo Palladian, Baroque & Neo Classical Craftsmanship

Neo Palladian, Baroque & Neo Classical Craftsmanship

Over a 32 year career master stonemason Stephen Critchley has worked on all types of architectural and design projects, but having been brought up in an area which has such a wealth of Neo Palladian and Neo Classical architecture, as well as the finest collection of Baroque architecture outside Rome, his particular interest became the period between the 1620′s – 1830′s. Added to this he was trained by a City of London company whose origins date back to 1690′s Aldgate and he happened to start his career at a time when many of these wonderful buildings were being restored and conserved for the first time for many decades.

This period, so rich in all the arts that flourished in England after Charles I’s trip to Spain in 1623 and architecturally given a boost by the destruction caused by the Great Fire of London in 1666 was the one Stephen chose to follow were ever possible. To learn as much about this field as he could Stephen travelled extensively searching out the few remaining masters of these styles in his early years, soaking up ever piece of knowledge. Skills ranging from choosing the best marble and limestone from quarries in Italy, France and Spain , geometric and visual techniques and classic hand tool skills peculiar to the highly decorated Baroque.

He has had the good fortune to have trained on and later produced work for many of the jewels of English architecture from this period and Stephen is now recognised as one of the top craftsmen working on the period from English Palladianism through Baroque to Neo Classicism in the field of architectural sculpture and stone masonry.

His experience in this field is unrivalled having over the years worked on and produced work for all for the following projects, as well as many others.

Years of working so closely with such high quality design and craftsmanship has lead to Stephen gaining a deep understanding of the design of this period and he is now one of very few craftsmen worldwide who still works with the techniques and visual proportions used at the time, many of which, closely linked in the Baroque with the explosion of baroque music through harmonic proportion.

On top of still working with the heritage left to us from this age, a great deal of Stephens work involves producing new carved stone and marble ornament, fire surrounds, statuary, funtains and heraldic carving in the style of and to the same standards as the original master craftsmen. He still hand carves each piece using the same tools and techniques used in the 16th and 17th Century. He believes hand carving is not a gimmick, but the best way to produce one off pieces of the highest quality when using natural materials to produce Bas, Mezzo and Alto relief as well as pieces in the round.

Over the last few years he has found an appreciation from a whole new range of clients. Where he used to supply mainly those with period properties, he now receives many commissions from people, for even the most highly decorated pieces to be set as a juxtaposition to modern design.

http://sjcritchley.com

http://www.youtube.com/watch?v=mXgLQq_-r5M

This period, so rich in all the arts that flourished in England after Charles I’s trip to Spain in 1623 and architecturally given a boost by the destruction caused by the Great Fire of London in 1666 was the one Stephen chose to follow were ever possible. To learn as much about this field as he could Stephen travelled extensively searching out the few remaining masters of these styles in his early years, soaking up ever piece of knowledge. Skills ranging from choosing the best marble and limestone from quarries in Italy, France and Spain , geometric and visual techniques and classic hand tool skills peculiar to the highly decorated Baroque.

He has had the good fortune to have trained on and later produced work for many of the jewels of English architecture from this period and Stephen is now recognised as one of the top craftsmen working on the period from English Palladianism through Baroque to Neo Classicism in the field of architectural sculpture and stone masonry.

His experience in this field is unrivalled having over the years worked on and produced work for all for the following projects, as well as many others.

Dates

|

Building

|

Architect / Designer

|

1617

|

Queen’s House, Greenwich

|

Inigo Jones

|

1626

|

York Watergate, Thames Embankment

|

Sir Balthasar Gerbier

|

1633

|

St Paul’s church, Covent Garden

|

Inigo Jones

|

1670

|

St Edmund, King and Martyr

|

Sir Christopher Wren

|

1677

|

St Peter upon Cornhill

|

Sir Christopher Wren

|

1690

|

Heythrop Foley

| |

1700′s

|

Stoneleigh balustrade

| |

1706

|

Heythrop Park, Oxfordshire

|

Thomas Archer

|

1712

|

Royal Naval Hospital, Greenwich

|

Sir Christopher Wren & Nicholas Hawksmoor

|

1716

|

St Mary Woolnoth

|

Nicholas Hawksmoor

|

1726

|

St Martin in The fields

|

James Gibbs

|

1730′s

|

Painswick House, Gloucestershire

| |

1730′s

|

Southam Manor, Gloucestershire

| |

1733

|

St. Luke’s church, London

|

John James & Nicholas Hawksmoor

|

1744

|

Woburn Abbey, Bedfordshire

|

Henry Flitcroft & Henry Holland

|

1750

|

Woburn Abbey South Stable Block

|

Henry Flitcroft

|

1770

|

Stoneleigh Abbey Conservatory

| |

1804

|

Russell Square, London, WC1

| |

1810

|

Dulwich Picture Gallery

|

Sir John Soane

|

1813

|

Tobacco Dock, London, E1

| |

1814

|

Charlesworthy Bridge, Stoneleigh

|

John Rennie

|

1815

|

Wheatley Park School, Oxfordshire

| |

1819

|

Somerset House, London, WC2

|

Sir William Chambers

|

1820′s

|

Chambers Bridge, Woburn Abbey

|

Sir William Chambers

|

On top of still working with the heritage left to us from this age, a great deal of Stephens work involves producing new carved stone and marble ornament, fire surrounds, statuary, funtains and heraldic carving in the style of and to the same standards as the original master craftsmen. He still hand carves each piece using the same tools and techniques used in the 16th and 17th Century. He believes hand carving is not a gimmick, but the best way to produce one off pieces of the highest quality when using natural materials to produce Bas, Mezzo and Alto relief as well as pieces in the round.

Over the last few years he has found an appreciation from a whole new range of clients. Where he used to supply mainly those with period properties, he now receives many commissions from people, for even the most highly decorated pieces to be set as a juxtaposition to modern design.

A selection of Stephen’s fire surrounds

As well as keeping this part of his craft alive himself Stephen also takes on 1 apprentice every 2 years to pass on his skills which were on the edge of disappearing only 30 years ago. These places are highly sought after, the training he gives is an extensive 5 year course as he believes in training the master crafts people of the future.http://sjcritchley.com

http://www.youtube.com/watch?v=mXgLQq_-r5M

Tuesday, 13 August 2013

Our Unique Selling Points

Recently while putting together a quotation for a client in the USA jointly with a London designer I was asked, what were my USP's. After asking isn't that something you plug into a laptop I was told it stood for Unique Selling Point and was necessary for the package being put together because obviously our USP's become a large part of those of the whole team including the designers.

We are a specialist high quality company and here are our

10 main Unique Selling Points.

1/ Bespoke service - We make all our pieces to exactly the size the client requires, as everything is made to order and does not come off the shelf, this bespoke service does not add time to the project.

2/ Hand carved in UK - Everything we supply is hand produced in the UK in either our Cotswold or East Anglian workshop. We do not use cheap labour or anything made in sweat shops.

Pictures above show the Laurel cushions being worked for the fire surround at the foot of this blog.

3/ Materials - We use only the best quality materials, never using lower quality to drive up our profits. We use limestone and sandstone from the UK and France; Slate from Wales and England and marble from Italy, France and Greece. The materials we use are those used by the likes of Michelangelo and Henry Moore and in the building of St. Paul's Cathedral; The Parthenon; The Doges Palace, Venice; The Palace Versailles and many others. Due to the continuity of the quarries we use we know the quality of the material and exactly how they will perform.

4/ Ocular rectification - Where enough information is given by the client we use ocular rectification when designing our fire surrounds etc. This allows for the direction natural light falls on the piece, from what direction it is mainly approached when and the size of the room it is to be fitted in etc. These are the same techniques used when producing the classic antique fire surrounds we now so admire.

5/ Design & drawing service - We can help with the design and proportions of your piece providing drawings for the clients approval before work commences.

6/ Training - Myself and my team are all fully trained, I myself was trained by a city of London company over 32 years ago and was lucky to have a connected training meaning my apprentice master started his training in 1946, his master 1920's, his in 1890's and so on. This is the sort of training teaches the tricks and techniques found in a practical craft not often found in books.

7/Training the next generation - Most companies do not put any thing back into training the next generation of stone masons. There are companies the employ 100 + and have no apprentices, we are a small skilled team of craftspeople and take a new apprentice at least every 2 years, which means we always have 2 or 3, this is a full apprenticeship and although the recognised training today is for much less we have our apprentices for 5 year as we aim to produce the master craftspeople of the future.

8/ Experience- Myself and my team have a vast experience in our field. Between us we have produced work for: The Palace of Westminster; Woburn Abbey; Stoneleigh Abbey; Somerset House; Buckingham Palace; Windsor Castle; Raglan Castle; Queen's House; Greenwich; St. Paul's Covent Garden; St. Martin's in the Field; Great Palm House, Kew; Heythrop House; Gloucester Cathedral; The British Museum; Dulwich Picture Gallery; Victoria & Albert museum; Chamber's Bridge; Wheatly Park; Charlesworthy Bridge; The Circle of Lebanon, Highgate and many Government and public buildings.

And for: The Aga Khan, The Sultan of Brunei, The Duke of Bedford, 2nd Baron Dickinson of Painswick, Lord and Lady Bamford, George Michael, Roger Dawtrey, and many others corporate and private clients.

9/ Web cam service - We offer a web cam service to allow the client to discuss their project with the craftsman whilst on the bench in real time. Also with all fire surrounds we provide a 3 minute film on a memory card of your actual fire surround being worked.

10/ Reproduction – We can exactly copy a fire surround or ornament of your choice whether it be an antique or contemporary piece, we are able to work from a photograph or a sketch .

http://sjcritchley.com

Wednesday, 31 July 2013

Luxury Design and Quality for All

Most of us assume that to commission a hand carved marble or stone fire surround, ornament or piece of statuary an over expensive and exclusive purchase. So when it comes to buying a fire surround or garden ornament we often look to the high street rather than approach one of our countries master craftsmen.

Today I am visiting Stephen Critchley one such craftsman, a master stonemason with the experience to make sure your purchase is as individual to you as the finest antique pieces now out of the reach of most was to it's original owner.

Stephen was trained by a City of London company and gained experience over a 30+ year career carving stone and marble for many of the south of England's most prestigious and historically important buildings including stately homes, Palaces and churches. Having worked at the top of the heritage and luxury design sectors for so long his list of past clients reads like a who's who of European and Asian Royalty and aristocracy with a good measure of other wealthy patrons thrown in.

Upon being asked to provide some modest fire surrounds in 2008 for a client who was unhappy with the quality he was receiving from his supplier, he says “I was totally shocked by the difference in quality between what we were producing and what the general public were being expected to accept.” Stephen decided at this time to use his and his teams experience and skill to offer top design and quality to all price ranges. As master stone mason Stephen works at the head of a small specialist team of craftspeople all of whom he has trained personally.

Stephen explains the market place is a wash with machine made items produced to the same couple of dozen designs in poor quality marbles and limestones. “There are a hand full of large companies in China churning our marble and stone ornament and through aggressive advertising they are stocking the vast majority of suppliers from the high street fireplace shop to the most expensive boutique London dealers.”

I watch him carving an acanthus motif on a piece of yellow Italian marble, while he explains “When we make a bespoke fire surround for a client we are making a piece to fit the actual room it's going into using ratios, proportional and visual techniques passed down through the master craftsman to his student. We are using the same visual tricks described by Vitruvious and used by Palladio and closer to home by Wren and Hawkesmoor.”

I think most will be pleasantly surprised by the cost of a bespoke service and the quality compared to the majority of new ornamentation and most antique pieces speaks for its self. Stephen tells me “People have the idea old is best but many of the antique fire surrounds being sold at present were never top quality in the first place but produced on the equivalent of a production line for the streets of houses springing up in the 18th and 19th century to accommodate the growing city populations. Remember in those day most fireplaces were made not a luxury item but a necessity.”

While Stephen continues to show me around his workshop he tells me how he sees the great resource of British crafts people being under used by designers and architects alike. “As in the past the designs we can produce are limitless taking note of classical designs or working with modern day designers.” With the staff on a break peace falls over the workshop and I get a chance to see the work in progress, I see plain contemporary and highly decorated Regency fire surrounds, a garden urn with goat head handles, a futuristic urn made from layers of stone and bubbly green glass, a coat of arms, two marble columns and a selection of windows and pieces of moulded architectural stone all in differing stages completion.

Just before leaving I ask Stephen how he stays so enthusiastic about his craft. “I am proud of the work we produce but proudest to be training new crafts people and helping to keep a quality craft and industry in this country.”

http://sjcritchley.com

(Article for South East Design Blog)

Saturday, 29 June 2013

One thousand years of working history

As well as a working master stone mason I am also Collegiate Assistant Clerk with the European Guild of Master Masons.

EGMM helped me when I was an apprentice and I was a member for 20 years before being asked to take over the Collegiate Assistant Clerks position in 2005, I was happy to accept and felt it my opportunity to give something back helping present and future craftsmen. Many are put off by the pomp and ceremony but I am proud to be involved with it, as it has formed over a many years and is the glue that holds together so many nationalities. When visiting a Hall in Italy or Turkey I feel instantly at home and in familiar surroundings even to the level of laughing with a fellow C. A. C about knocking over chairs when wearing your gown.

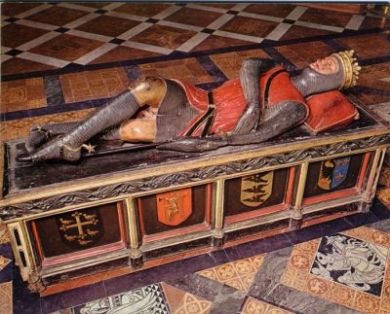

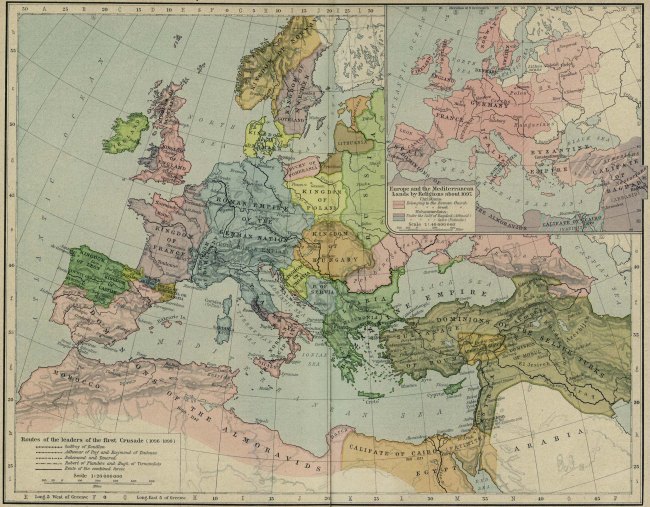

EGMM is a little known craftsman's guild formed around 1096 by Robert Duke of Normandy, among others, as part of the craft arm of the first Crusade to support the knights and their followers. At this time they became closely linked with the orders of monastic knights which explains many of our ceremonies and titles still used.

Robert of Normandy, Gloucester Cathedral

Originally formed across 12 city and national boundaries, there remain 12 companies within the Guild still known by their original names; Normandy, Holy Roman Empire, Byzantine Empire, Leon & Castile, Burgundy, Aragon, Catalonia, France, Zaragoza, Brittany, Venice & Navarre. Mainly states that one way or another were involved with the initial venture.

We have one Grand Master, 12 Masters, 12 Clerks, 12 Collegiate Assistant Clerks and Company Assistant Clerks, one for each company. In the UK or Normandy company we also have Wardens (upper and rented), and a Beadle in the manner of the Medieval Guilds.

Grand Master is a life long position, the Master of each company is elected quinquennially, the Clerk is the company's accountant, the Collegiate Assistant Clerk deals with education, training and helping members, and the Company Assistant Clerk deals with the running of the company and ceremonies.

Today it is a self financing, non profit making organisation truly diverse both racially and religiously, our company's ceremonial traditions cover the Jewish, Catholic, Orthodox Christian, Muslim and Protestant religions.

Throughout the turbulent history of Europe EGMM has kept it's head below the parapet, carrying on quietly with it's work, allowing the organisation to continue for over 1000 years virtually unknown and unmolested. Rather than giving a little help to the many, the ethos has always been to give total help and support to a few, as it was always the intention to nurture future craft masters, not jacks of all trades.

The Guild no longer has any connection with masonry projects as such, but through our members in over 20 modern countries we assist in training and education through our vast technical and historical archive and in the form of funding.

We still run several almshouses and supply financial help with bills etc. to elderly past members. This harks back to medieval times when we looked after the families of dead or injured members, helped with the education of their children and arbitrated between them and their employers or clients when needed. In the UK we were the forerunner to the operative stonemasons societies http://www.unionancestors.co.uk/Stonemasons.htm and a template for the early trade unions.

http://sjcritchley.com

Sunday, 23 June 2013

Bring the quality of British craftsmanship from the heritage sector and high end design to all price ranges.

I am passionate about getting people to buy hand carved pieces produced by experienced craftsmen rather than those mass produced, machine made, items as sold by the industry leaders.

The business model the majority use seems to me to be out of date and from a time when less interest was taken in environmental issues and the cultural importance of real craftsmanship to society was not recognised. It is definitely not what my clients expect from me these days.

Through displays and talks etc. I am working to dispel the myth that we do not have world class craftsmen in the UK. Though our sales in the US, Europe & Asia and the feed back we receive we know of the high esteem with which British craftsmanship in general is held, it seems the only people we need to convince are the British themselves.

Reasons to buy craftsman made hand carved ornament.

Higher quality at no extra cost:

Why would you buy a piece that is exactly the same as everyone else has when you can commission a custom made item, hand carved by craftsmen who are also producing work for palaces, stately homes and high end design projects across the UK, Europe and the rest of the world? There is actually little or no extra cost. People assume hand carved is considerably more expensive than machine made. For individual bespoke pieces this is not the case, there is no need for machine set up for hand carved items and you are not paying for the item to be shipped half way around the world.

Highest quality materials:

As our reputation is based on the quality of our work we use only the best materials available. We use limestones and sandstones from the UK and France, some having been used since the time of the Roman Empire. We also use Welsh and Cumbrian slate and marble from the UK, France, Italy and Greece. Often the same materials used by the ancient and renaissance masters.

Give a face to the craftsman:

We offer a service where the client, at an arranged time can talk directly to the craftsman with their piece on the bench in front of them via web cam. Yes the actual craftsman, not an extra brought in from the office or warehouse for the occasion. This takes advantage of the years of expertise and knowledge gained by the craftsmen regarding material, proportion, and visual tricks such as ocular rectification. We also supply a short 3 minute film for all our projects of the piece being worked free of charge upon delivery.

Quicker turn around for bespoke pieces:

We are approached regularly by clients who have been quoted 12 weeks for the most minor of adjustments from the industry leaders. For all but the most intricate piece we aim for a turn around of 28 days or less for their bespoke item.

Lower carbon foot print:

We hear a lot about peoples concerns regarding carbon foot print and the distance products travel but the large majority of off the shelf fire surround in the UK are travelling over 10, 000 kilometres or 6,000 miles to get to you, if you have paid more and get the real material you can double those distances as the stone has to get from Europe to their workshops in the first place. By using the acknowledged best quality limestones and sandstones, we source from quarries lest than 250km or 150 miles away and for the best marbles in the world the furthest they should come is 1,500 km or 900 miles.

Support for UK jobs and training.

By purchasing quality bespoke items produced by trained craftsmen in the UK you are supporting a traditional industry and quality skilled jobs, also allowing us to train more people thus building a healthy human crafts resource for now and the future.

And last but not least

We know from conversations with our existing clients how being able to provide such a bespoke service for their customers gives them a priceless advantage over many of their competitors and is complimentary to the quality services they already offer.

http://sjcritchley.com

My work encompasses all architectural and design types

My work encompasses all architectural and design types including Gothic, Edwardian, Victorian, contemporary and modern, I am especially experienced in the period from the English Renaissance through English Baroque to Regency sometimes in design circles loosely named the English country house style.

In addition to training with a City of London company whose origins date back to 1690's Aldgate, I have over 30 years experience working in and around The City of London, also working extensively in Georgian Bath and Cheltenham Spa.

I gained experience and expertise whilst conserving and carving new architectural stone and interior pieces for some of the great palaces, stately homes, country house and churches in Britain, such as Queen's House Greenwich, Woburn Abbey, Somerset House, St. Martin's in the Fields, St. Paul's Covent Garden, and Heythrop House.

This gave me an insight and a greater understanding when interpreting and carving fire surrounds and ornamentation from designs by the likes of Inigo Jones, James Gibbs, William Chambers, Henry Flitcroft and from the contemporary pattern books by Batty Langley and William Halfpenny.

More recently, as well as the minimal contemporary ornament we have been making for interior designers for town houses and apartments we have been producing many more classically inspired pieces used as a juxtaposition to the decoration in a modern setting . Fire surrounds, urns and pedestals, finials, columns, water features, panels, busts and statuary are all regularly produced.

A large proportion of our design work involves carving fire surrounds to the design of an antique piece for architects and designers, the advantage of this for the client is, the antique although beautiful was made to suit a specific space, as such much of the design and thinking that went in to the piece is now lost when placed in a new setting.

A new piece of the same quality and in many cases exactly the same material as the original can be produced allowing for the proportional changes to its surroundings and for ocular rectification to allow for light fall etc.

These pieces are by no means just copies, they are new original pieces in the same way as the piece we are working from is an original in the style of a classical design or which ever style it may be. There is no need make do when it comes to dimension or material.

Although all our fireplaces and ornamentation are still hand carved using techniques, tools and materials virtually unchanged since the 17th century, we do use technology to give a better service to the client. For example via web cam my clients can see their item on the bench in one of our UK workshops and talk to us in real time to discuss materials, design dimensions etc.

Although all our fireplaces and ornamentation are still hand carved using techniques, tools and materials virtually unchanged since the 17th century, we do use technology to give a better service to the client. For example via web cam my clients can see their item on the bench in one of our UK workshops and talk to us in real time to discuss materials, design dimensions etc.

I supply items worldwide to dealers, architects, designers, developers, galleries and the public, with my main markets outside the UK being the USA and Asia.

http://sjcritchley.com

Monday, 10 June 2013

Go for Quality

Many companies claim they hand carve

fire surrounds and other ornaments themselves, however, the vast

majority, including most of the brand leaders actually buy their fire

surrounds from China or some other country with low labour costs

where they are largely machined.

Carrara, instead of being the top

quality marble as used by Michelangelo becomes any old white marble

or in some cases not marble at all but quartzite, which in fact

dissolves in hot water and Bath stone that has never seen south

western England. Remember, when buying these inferior materials the

financial saving is not passed down to you the client, it pays for

the plush showrooms, expensive web sites, ads in glossy magazines and

half a dozen reps - in fact nothing that adds to the quality of the

piece.

Before obtaining a quotation there is

an assumption that hand carved is much more expensive than machine

made, but this is often not the case.

When a company claims to produce their

own items: ask where their workshop is, ask to talk to one of their

craftsmen., ask where the stone comes from and a little about it, ask

where they trained and what is their experience, and ask why it takes

12 weeks to take delivery of a fire surround that needs altering by

25 mm to the one in the shop.

The problem is, many members of the

public are impressed by expensively designed shops in the right post

code. In the future, when children and grandchildren are discussing

their predecessors hand carved commission, would you rather they

were saying “he got it from a dealer in Kensington who later sold

cars, he was a very good salesman and they had lovely brochures” or

“ the man who carved this also carved work for Windsor Castle and

for the Duke of Bedford at Woburn Abbey”.

We are not fire surround manufacturers

or water feature makers, we are stonemasons and architectural

sculptors. We carve all types of fire surrounds, fountains, urns,

etc. It is only coming back to the design sector from heritage and

high end commissions that I notice the lack of quality being offered,

all in the name of greater profits for those jumping on a gravy

train.

Don't buy from a middle man, go direct

to the craftsmen. You may not get your plush showroom but you do

get the true bespoke experience and a hand carved piece wholly

original, and an antique of the future.

http://sjcritchley.com

Wednesday, 22 May 2013

Art Deco Dove

An Art Deco dove I carved for a client a while ago in the style of Joel Martell.

http://sjcritchley.com

Subscribe to:

Posts (Atom)